You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Formula Jr. project

- Thread starter Woobs

- Start date

Woobs

New member

Only -1*C today so, perfect for outside work  . Too bad the sun wasn't out.

. Too bad the sun wasn't out.

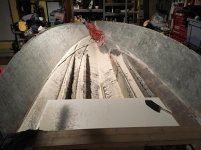

I got the port side interior hull all ground down to glass. Here's pics of both sides so you can see what it looked like before. and a close up of the rough glass.

I don't know what it was painted/covered with but it was pretty thick in spots and it sure adhered well.

I got the port side interior hull all ground down to glass. Here's pics of both sides so you can see what it looked like before. and a close up of the rough glass.

I don't know what it was painted/covered with but it was pretty thick in spots and it sure adhered well.

Attachments

Last edited:

Woobs

New member

PROGRESS on the JR!

Was supposed to go boating today for our last run of the year but, the weather looked crappy.....

So, I went to play with the Jr.

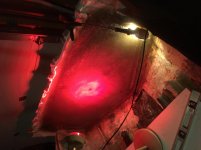

I made a small repair at the transom to see how the vinylester would work with 14*C temperatures. It did just fine so, I cut out some sheets of 1708 and 1808, fit them and laminated them to the false (melamine) transom.

1st course lay inside the edges of the transom lip. 2nd course overlapped by 2", 3rd... another 2" . The 4th covered the entire transom and wrapped around to the sides of the hull and the bottom by about 3"

I used a small space heater and a heat lamp to ensure the vinylester has the best opportunity to cure.

Overall, it looks pretty good. I'm quite happy for my first ever attempt at glasswork. However, I need more thickness before I can install the marine ply core. So, back to the composites shop Monday!

Was supposed to go boating today for our last run of the year but, the weather looked crappy.....

So, I went to play with the Jr.

I made a small repair at the transom to see how the vinylester would work with 14*C temperatures. It did just fine so, I cut out some sheets of 1708 and 1808, fit them and laminated them to the false (melamine) transom.

1st course lay inside the edges of the transom lip. 2nd course overlapped by 2", 3rd... another 2" . The 4th covered the entire transom and wrapped around to the sides of the hull and the bottom by about 3"

I used a small space heater and a heat lamp to ensure the vinylester has the best opportunity to cure.

Overall, it looks pretty good. I'm quite happy for my first ever attempt at glasswork. However, I need more thickness before I can install the marine ply core. So, back to the composites shop Monday!

Attachments

Woobs

New member

Thanks. That's where the old Chrysler sterndrive used to live. Similar to this one...Cool project. What is up with the huge round hole in the transom in the early photos?

Attachments

Woobs

New member

Well, I've run out of time and temperature this year.... The weather has turned too cold to glass and it looks to stay that way until spring. At least I got 8 courses of layup on the transom and the marine ply core bonded shaped and sanded (ready for installation. Man, 1 more day and it'd be done!

I suppose there's always some more grinding I could do while I wait

I suppose there's always some more grinding I could do while I wait

Attachments

Woobs

New member

Big day today!

Off comes the false transom so I can see glass the results from aft. 9 courses total of 1708 & 1808 is about 3/8".

Also, fit the wood core. Waiting for spring to laminate it to my new perfectly flat glass transom.

Trimmed the top and it looks like a boat again

Off comes the false transom so I can see glass the results from aft. 9 courses total of 1708 & 1808 is about 3/8".

Also, fit the wood core. Waiting for spring to laminate it to my new perfectly flat glass transom.

Trimmed the top and it looks like a boat again

Attachments

Last edited: