Slowlearner

Member

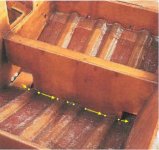

So fellas I had a post going about a " elevated " moisture reading in my center stringer. I am sure by now we all know that its a hollow box design. Well upon further investigation of the bilge and the stringer Ive found the entry point of the water. Formula has drilled 2 or 3 small holes in the bottom of the stringer on both port and starboard sides of the stringer. My surveyor never told me the level of moisture in the stringer so ive bought my own moisture meter and it should be here next week. Ive created this post as a warning to everyone with a 330 no matter the vintage. Please check the bottom of your stringer and if your in starage with a dry bilge seal the holes up with 5200. I am hoping my levels of moisture are not detrimental to where i can work with my situation and dry it out seal off the holes and carry on.....